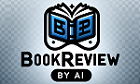

Chapter 1: The Lean Six Sigma Revolution

* Summary: Introduces Lean Six Sigma, a process improvement methodology that combines Lean and Six Sigma.

* Real Example: A manufacturing company struggling with delays and defects implements Lean Six Sigma, streamlining processes and reducing waste.

Chapter 2: Understanding the DMAIC Framework

* Summary: Describes the DMAIC framework (Define, Measure, Analyze, Improve, Control) used in Lean Six Sigma projects.

* Real Example: A customer service team uses DMAIC to identify and address long wait times, leading to improved customer satisfaction.

Chapter 3: Define the Project

* Summary: Explains the process of defining the project goal, scope, and customer requirements.

* Real Example: A healthcare organization uses Lean Six Sigma to improve patient wait times for surgery, setting a specific target reduction goal.

Chapter 4: Measure the Current Process

* Summary: Covers data collection techniques and process mapping to measure the current state of the process.

* Real Example: A software company uses data analysis and process mapping to identify areas of inefficiency in its development cycle.

Chapter 5: Analyze the Data

* Summary: Describes statistical tools and techniques for analyzing data and identifying root causes of problems.

* Real Example: A supply chain team uses a cause-and-effect diagram to determine that supplier delays are the main contributor to inventory shortages.

Chapter 6: Improve the Process

* Summary: Explores brainstorming, prototyping, and implementation of solutions to improve the process.

* Real Example: A retail store implements a new inventory management system to streamline ordering and reduce out-of-stock situations.

Chapter 7: Control the Process

* Summary: Emphasizes the importance of monitoring and maintaining improvements over time.

* Real Example: A manufacturing plant sets up control charts to track process performance and identify any deviations from the desired state.

Chapter 8: Lean Six Sigma Tools and Techniques

* Summary: Provides an overview of common Lean Six Sigma tools and techniques, such as value stream mapping, kaizen, and Kanban.

* Real Example: A manufacturing team uses value stream mapping to visualize and optimize the production process, reducing lead times and waste.

Chapter 9: Lean Six Sigma in Different Industries

* Summary: Discusses the applicability of Lean Six Sigma in various industries, including manufacturing, healthcare, and finance.

* Real Example: A financial services company uses Lean Six Sigma to streamline loan processing, improving turnaround time and increasing customer satisfaction.

Chapter 10: Lean Six Sigma Certification

* Summary: Outlines the benefits of Lean Six Sigma certification and provides guidance on obtaining it.

* Real Example: A quality manager earns Lean Six Sigma Green Belt certification, demonstrating expertise in process improvement and leading improvement projects.