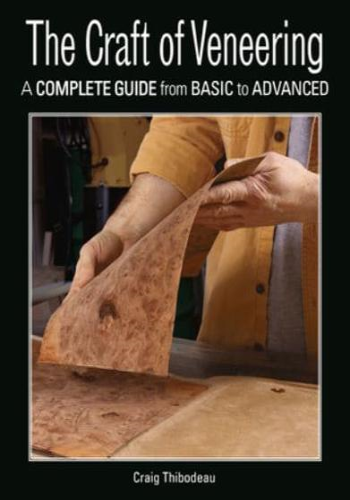

Chapter 1: Introduction to Veneering

* Definition and history of veneering

* Types of veneers and their applications

* Benefits and limitations of veneering

Real Example: Crafting a decorative wooden box by veneering with a burl veneer to achieve a unique and elegant look.

Chapter 2: Preparing the Substrate

* Selecting the appropriate substrate for veneering

* Cleaning, flattening, and preparing the surface

* Applying size and pressure to ensure adhesion

Real Example: Preparing a plywood substrate for veneering with a cherry veneer by sanding, cleaning, and applying thin glue.

Chapter 3: Cutting and Laying Up Veneers

* Techniques for cutting and matching veneers

* Laying up veneers in different patterns and orientations

* Controlling the grain direction and grain matching

Real Example: Creating a marquetry pattern by cutting and assembling veneers of different woods and colors into a geometric design.

Chapter 4: Pressing and Laminating

* Methods for pressing veneers onto the substrate

* Selecting the appropriate pressure and temperature

* Troubleshooting common problems during pressing

Real Example: Using a vacuum press to laminate a walnut veneer onto a table top to achieve a smooth and durable finish.

Chapter 5: Trimming and Finishing

* Trimming excess veneer around the edges

* Sanding, scraping, and scraping to refine the surface

* Applying protective coatings to enhance durability

Real Example: Trimming and finishing a veneered door by sanding, applying a water-based polyurethane, and polishing to create a lustrous and scratch-resistant surface.

Chapter 6: Advanced Veneering Techniques

* Complex veneer patterns and designs

* Inlaying and marquetry

* Bending and forming veneers

Real Example: Creating a curved veneer panel for a chair back by using steam bending techniques to shape the veneer around a form.

Chapter 7: Troubleshooting Common Problems

* Identifying and resolving issues with veneer adhesion

* Preventing and repairing veneer bubbles and cracks

* Dealing with discoloration and staining

Real Example: Troubleshooting a veneer bubble that forms during pressing by releasing the pressure and applying additional glue before re-pressing.

Chapter 8: Tools and Equipment for Veneering

* Essential tools for the veneering process

* Selecting the right equipment for specific applications

* Maintaining and care for tools and equipment

Real Example: Investing in a high-quality veneer saw to ensure precise and clean cuts that result in a better-looking veneer surface.