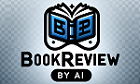

Often playing second fiddle to hops in the minds of craft beer drinkers, malt is the backbone of beer: "No barley, no beer." Malt defines the color, flavor, body, and alcohol of beer and has been cultivated for nearly as long as agriculture has existed. In this book, author John Mallett explains why he feels a book on malt is necessary, taking the reader on a brief history of malting from the earliest records of bappir through to the Middle Ages and Early Modern Period. When Mallett touches on the major changes wrought by the Industrial Revolution and beyond, he illustrates how developments in malting technology were intertwined with politics and taxation, which increasingly came to bear on the world of maltsters and brewers.

Of course, no book on malt would be complete without a look at the processes behind malting and how different malts are made. Mallett neatly conveys the basics of malt chemistry, Maillard reactions, and diastatic power-the enzymes, starches, sugars, glucans, phenols, proteins, and lipids involved. Descriptions of the main types of malt are included, from base malt, caramel malts, and roasted malts through to specialty malts and other grains like wheat, rye, and oats. Information is interspersed with the thoughts and wisdom of some of America's most respected craft brewers.

Understanding an ingredient requires appreciating where it comes from and how it is grown. The author condenses the complexities of barley anatomy and agriculture into easy, readable sections, seamlessly combining these details with high-level look at the economic and environmental pressures that dictate the livelihoods of farmers and maltsters. Mallett explains how to interpret-and when to rely on-malt quality and analysis sheets, an essential skill for brewers. There is a summary of the main barley varieties, both modern and heritage, from Europe and America. The book finishes with what happens to the malt once it reaches the brewery, addressing issues of malt packaging, handling, preparation, storage, conveyance, and milling in the brewhouse.